| ||

| FR | | LABORATORY & WORKSHOP | PLATINUM-PALLADIUM | LARGE FORMAT | OTHER PROCESSES | TOOLS | TRAINING COURSES |  |

| Platinum-Palladium | ||||||||||||||||||||||||||||||||

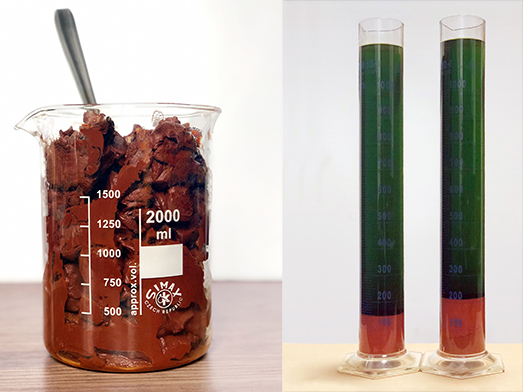

| For platinum-palladium printing, ensuring the regularity, quality and longevity of prints is essential. | For platinum-palladium printing, guaranteeing the regularity, quality and longevity of prints by purchasing reliable consumables on the one hand, and using appropriate tools on the other, is essential.The choice of paper, the preparation of chemicals at the laboratory, the constancy of the paper’s drying and humidification, the precision of the contact between the negative transparency and the paper during UV exposure and the quality of the washing are all factors that contribute to the production of exceptional prints. | |||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||

| Large formats | ||||||||||||||||||||||||||||||||

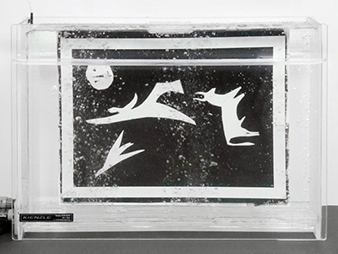

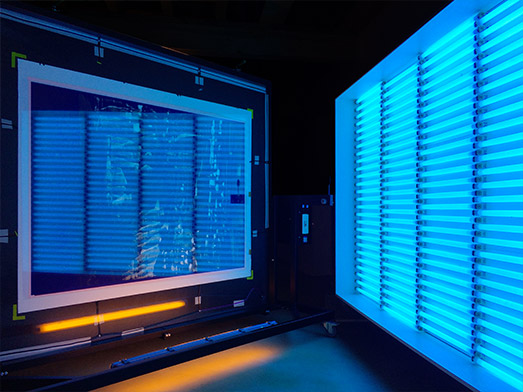

| Our fully-equipped workshop allows us to produce large format contact prints. | The workshop is equipped with an exposure unit and with processing material that allow for the production of contact prints of up to 1.30m in width and 2.10m in length. Contact between the inkjet negative transparency and the paper is created by the vacuum of the exposure unit. This procedure guarantees an optimal sharpness of the image, regardless the type of paper. The prints are developed in a rocking tray that keeps processing regular and improves the quality of successive washings. | |||||||||||||||||||||||||||||||

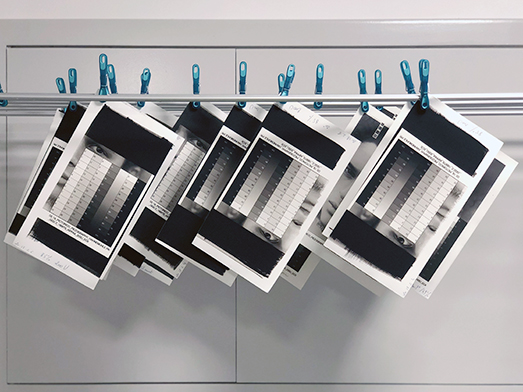

Vacuum exposure unit and UV exposure unit |  Deville in-sink tray rocking system, 130x210cm

| |||||||||||||||||||||||||||||||

|  | |||||||||||||||||||||||||||||||

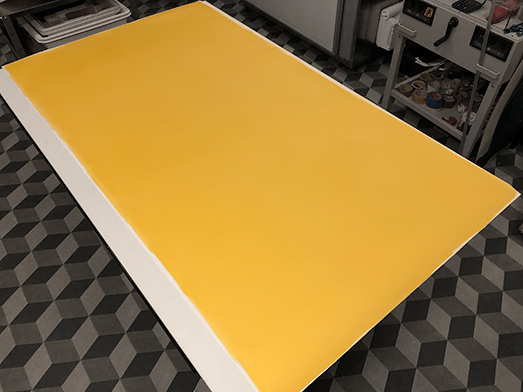

| 110x210cm cotton paper sheet sensitized with platinum-palladium | In-sink tray rocking system Processing of a platinum-palladium print 110x195 cm | |||||||||||||||||||||||||||||||

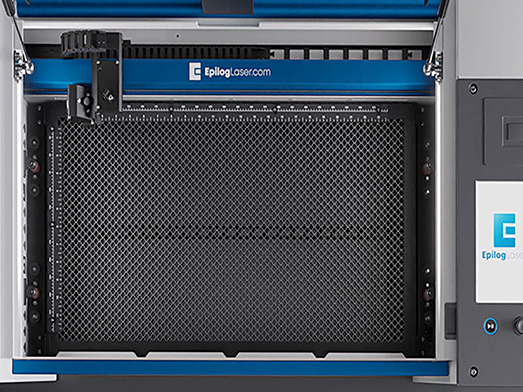

| Digital printing, intaglio and laser engravings | ||||||||||||||||||||||||||||||||

| Likewise, in order to maintain regularity and precision, the outputs of the screens are regularly calibrated and the printer and the laser engraver adjusted. | With the same concern for regularity and precision, the outputs of the 24', 31' and 86' screens (Eizo and Iiyama) and the laser engraver are regularly calibrated. The Epson printer dedicated to printing black and white negatives is also suitable for all media: matte, satin and glossy, up to 110 cm wide and 1.2 mm thick and the intaglio press accepts plates and papers up to 100 cm wide. | |||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||

| Finishing | ||||||||||||||||||||||||||||||||

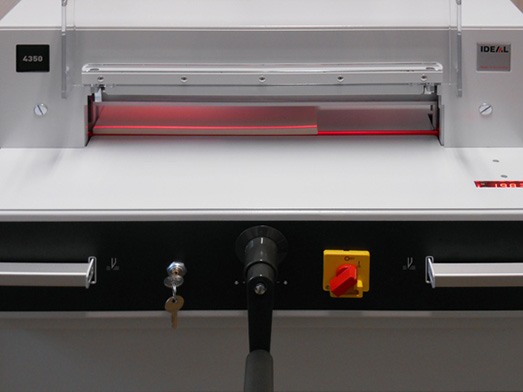

| Once they have been dried and retouched, most platinum-palladium prints have to be pressed and smoothed out. This also applies to certain types of paper used for inkjet prints, especially the finest ones. | The heated vacuum press allows to press prints of up to 90x120cm in size. A guillotine cutter equipped with a digital display allows precise and perfect cuts when making portfolios of up to 47x47cm in size and 8cm thick. |

|||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||

|

12, rue Orbe 64270 Salies-de-Béarn - France C +33 (0)6 32 22 51 11 email : lafolie.laurent@orange.fr |